I.Advantages:

1.The brewing pipeline conforms to the beer brewing process, is simple to operate, easy to clean and operate; adopts the method of entering the wort from the side to reduce the oxidation of the wort;

2.Energy saving: the hot water is recycled to the hot water tank, and the condensed water is recycled to the boiler;

3.Labor-saving: automatic temperature control, PLC system to assist you in brewing; automatic variable frequency tiller and mixing improve work efficiency;

4.Adopting advanced world famouse brand components to ensure the smoothly running;

5.Support different heating way, steam, direct fire and electric, depending on site and local utility costs.

6.High-quality stainless steel material 304 or 316 and exquisite appearance.

7.Brewing vessel and fermentation tanks are tested prior to shipment to avoid on-site repairs, guarantee uninterrupted startup and assured vessel performance.

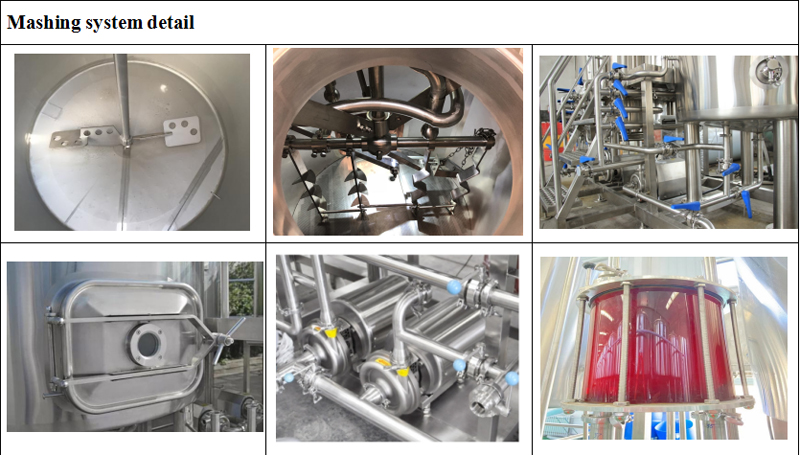

II.Product detail: 3BBL Nano brewery equipment

Specifications

Brewhouse Capacity: 3BBLitre/brew with combination vessel

Standard Configurations

2.Combined Brewhouse System, 200L:

1).Mash/Brew Kettle/Whirlpool, Function: mashing, wort boiling and whirlpool.

1.Temperature measurement method: PT100 temperature probe.

2.Heating system:direct fire heating with combustion chamber.

3.Cleaning method: 360°Fixed rotate cleaning ball.

4.Machinical Agitation: With VFD control, at the top horizontal motor with seal.

5.Steam venting chimney with anti backflow pipe.

6.With level display and necessary valve.

2).Lauter tank, Function: lauter, filter the wort.

1. Sparging pipe for grain washing with TC connection.

2.Wort collecting pipe and back washing device to cleaning false bottom.

3. Mechanical Raker: VFD control, stirring motor on the top.

4. Spent grain:Automatic raker device, Grain removing plate with reverse, forward is raker, reverse is grain out.

6. Milled false bottom: 0.7mm distance, diameter designed suitable for the lauter tun, with dense supporting leg, detachable handle.

7.Wort circulation inlet TC on top with elbow and mash inlet upon false bottom on side wall.

8.Side mounted spent grain port .

4).Hot liquid tank for optional, Function: hot water heating

1.Interior finish: packling pasivition without dead corner.

2.Heating method: steam heating, steam jacket 1.5mm.

5).Brewhouse pipes, Function: wort transfer from mash tun to lauter, and to kettle and so on.

1.Material: SS304 sanitary pipes.

2.Sanitary stainless steel valve and pipeline, Easy to operate and reasonable in design;

6).Plate heating exchanger, Function: wort cooling.

1.Two stage and six flow, hot wort to cold wort, tap water to hot water, glycol water recycle.

2.Design Structure: Suspension type, screw material

is SUS304, nut material is brass, easy disassembled

for cleaning.

3. Stainless steel 304 material

4.Design pressure:1.0 Mpa;

5.Working temperature:170°C.

9.Tri-clamp quick-installed.

3.Brewery Fermentation system:

1).Glycol Jacketed Conical fermentation tank, Function: beer fermenting and cooling

1.All AISI-304 Stainless Steel Construction

2.Jacketed & Insulated

3.Dual Zone Dimple Cooling Jacket

4.Dish Top & 60° Conical Bottom

5. Stainless Steel Legs with Leveling Ports

6.Top Manway or Side Shadow less Manway

7.With Racking arm, Discharge Port, CIP Arm and Spray Ball, Sample Valve, Shock proof Pressure Gauge, Safety Valve, Thermowell and Pressure regulator valve.

2).Yeast brink

Function: A yeast brink is a stainless steel keg that has been modified to collect yeast from a conical fermenter to be saved, and pitched again into a new batch of beer.

5.Cooling Unit

1).Glycol water tank, Function: glycol water storage

2).Cold liquid tank for Optional: Function: cooling wort cooler.

3).Glycol chiller: Function: cooling the glycol water.

Assembly unit, wind cooling, enviromental refrigerant: R404a or R407c, compressor and electrical part meet UL/CUL/CE certification.

6.Cleaning Unit

1).Caustic tank: Elctric heating element inside, with anti-dry device for safety.

2).Sterilization tank: Stainless steel vessel.

3).Control and pump:Portable sanitary CIP pump, SS cart and controller.

7.Controlling Unit

1).Brewhouse and fermenting controlling.

Manual button control panel or PLC control with touch screen for option, with RTD&Solenoid valves.

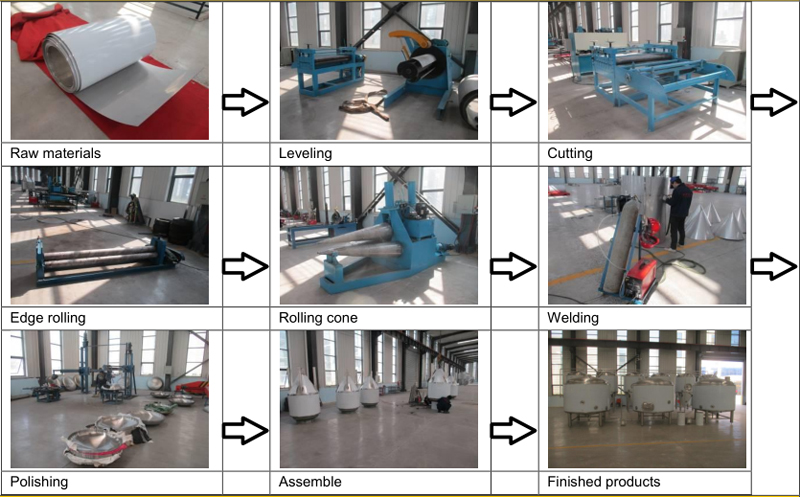

III.Production Process

Jinan Alston Equipment Co.,Ltd.

Jinan Alston Equipment Co.,Ltd.