● Higher wort wort extract

● Lower energy cost and material consumption

● Well adjusted temp and water blending unit for better grain and water mixing

● Special designed steam jacket unit to increase steam using efficiency and avoid “water hammer” problem

● Special tank and piping construction to avoid the wort aeration problem and decrease the material lost

● Internal heater for separate kettle, working with cylinder and bottom jacket for better boiling effect.

● Possible to make boiling process under pressure, especially for brewery at higher altitude.

● Special designed steam condensing unit, with both steam condensing and water heating function

● Cellar tanks with good design updating for better cooling effect and accurate temp control

● Pre assembled cellar piping, with cat walks for operation on top or manifold or piping corridor

● Cooling unit for current use and well prepared for future expanding

● Automation system with curve indication and production record printing, with recipe storage function, clients can create new recipe as the exact production requirement.

Basic configuration:

● Grain handling: Mill, conveyor (flexi auger or chain disc), hopper etc. With weight scaling

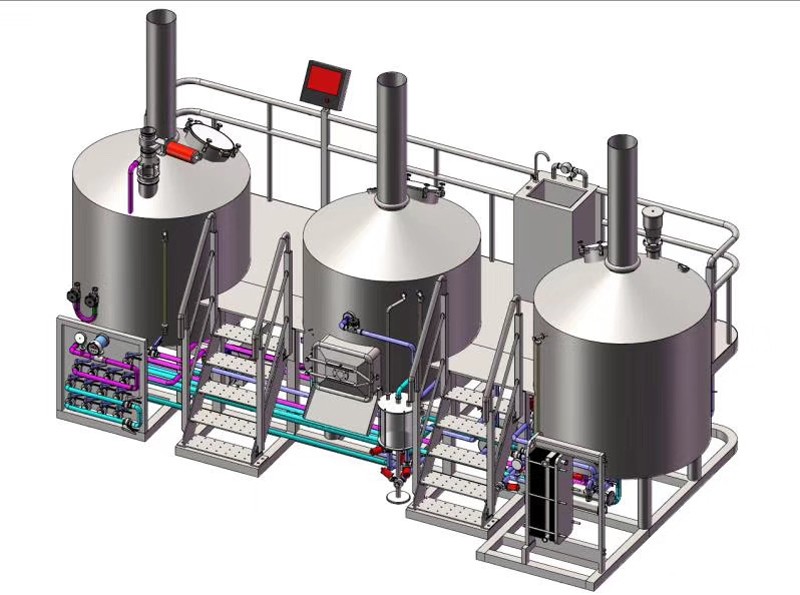

● Brewhouse: Three or four vessels, including piping, HE etc.

● Cellar: Fermenter, storage tank and BBTs, for fermentation of different kinds of beer, all assembled and isolated

● Cooling: Chiller connected with glycol tank for cooling, with ice water tank and plat cooler for wort cooling

● CIP: Fixed CIP station or Portable CIP unit

● Filtration: Diatomite filtration, membrane filter, Plate frame filtration unit etc.

● Compressed air unit and N2 generator, all piping line connected with system

Jinan Alston Equipment Co.,Ltd.

Jinan Alston Equipment Co.,Ltd.