Homebrewing beer on a nano scale opens up the ability for specialty craft brewers to experiment with unique ingredients and flavors on a small production system before potentially scaling up to larger commercial brewing. Setting up a 1-3 barrel nano brewhouse allows creative freedom without major capital investment. Nano brewery equipment guide covers key considerations for designing and operating a nano brewery.

Nano Brewery Equipment Types

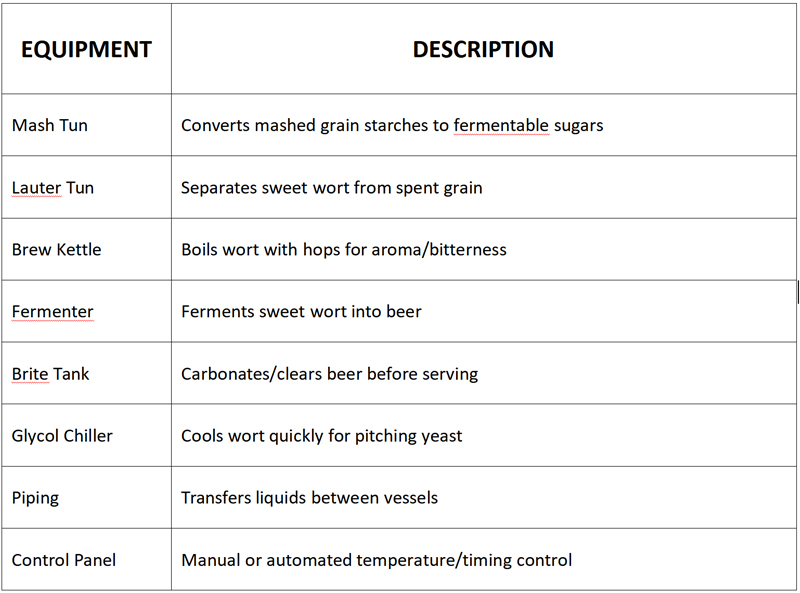

The core components of a nano brewhouse include:

Additional equipment may include:

Grist Case – Holds/feeds grain

Mill – Crushes malt kernel

Whirlpool Unit – Settles hops/coagulants

Heat Exchanger – Cools hot wort quickly

Air Compressor – Pressurizes fermenters

Filter – Clarifies/sterilizes beer

Kegs – Serves final product

Nano brewery equipment Sizing Considerations

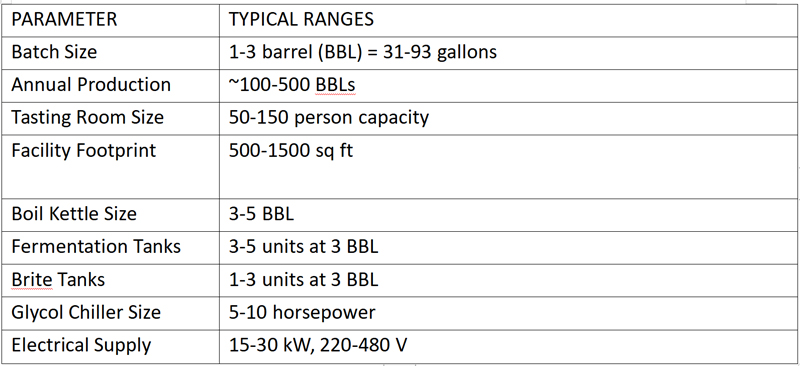

When designing a nano brewery, key factors determining equipment size and layout include:

Layout Options

Standard nano brewhouse configurations include:

Linear – Equipment in row

L-shape – Efficiency footprint

Cluster – Grouped vessels

Multi-level – Save floorspace

Customization

While 1-3 BBL nano systems are available turnkey, customization allows:

Unique vessel shapes/sizes

Specialized equipment like open fermenters

Match brewery design aesthetic

Installation & Operation Guidance

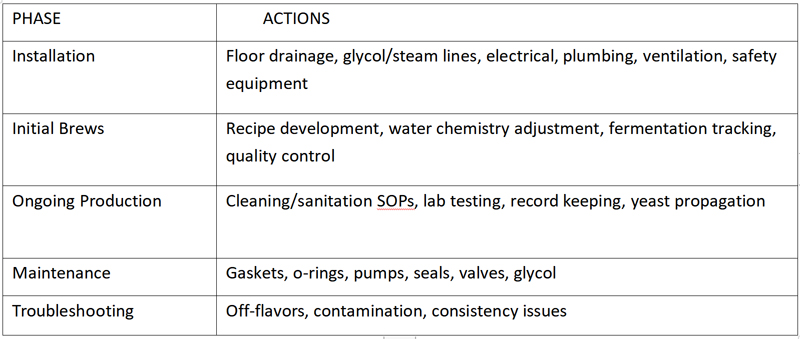

Key considerations for installing and operating a nano brewhouse:

Jinan Alston Equipment Co.,Ltd.

Jinan Alston Equipment Co.,Ltd.