Bright beer system

Specifications:

Working Capacity: 100L-3000L.

Inner Diameter: Requirement.

PU Insulation: 80-100mm

Outside Diameter: Requirement.

Thickness: Inner Shell: 3 mm, Dimple Jacket: 1.5 mm, Cladding: 2 mm

Detail:

Beer maturation/conditioning /serving/filtered beer receiving.

1.All AISI-304 Stainless Steel Construction

2.Jacketed & Insulated

3.Dual Zone Dimple Cooling Jacket

4.Dish Top & 140° Conical Bottom

5.Stainless Steel Legs with Leveling Ports

Bright beer tank Includes:

1.Top Manway or Side Shadow less Manway

2.Racking Port with Tri-Clover Butterfly Valve

3.Discharge Port with Tri-Clover Butterfly Valve

4.2 Tri-Clover Outlets with Butterfly Valves

5.CIP Arm and Spray Ball

6.Sample Valve

7.Shock proof Pressure Gauge

8.Safety Valve

9.Thermowell

10.Level sight

11.Carbonation stone

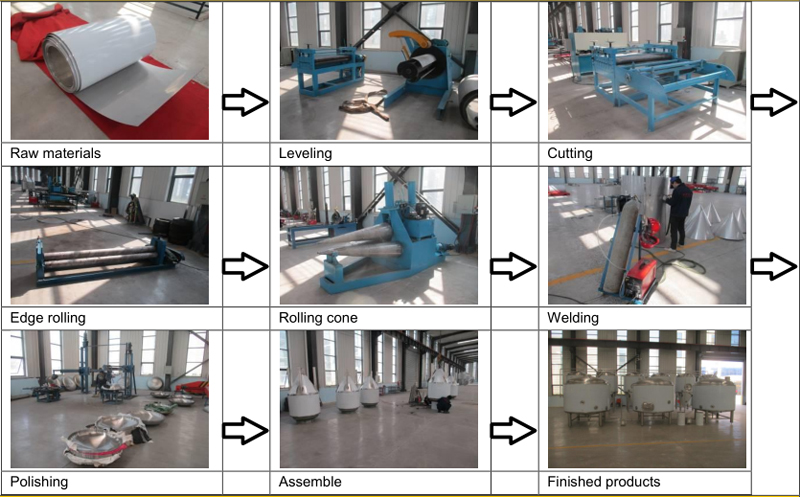

III.Production Process

Jinan Alston Equipment Co.,Ltd.

Jinan Alston Equipment Co.,Ltd.