I.Advantages:

1.The brewing pipeline conforms to the beer brewing process, is simple to operate, easy to clean and operate; adopts the method of entering the wort from the side to reduce the oxidation of the wort;

2.Energy saving: the hot water is recycled to the hot water tank, and the condensed water is recycled to the boiler;

3.Labor-saving: automatic temperature control, PLC system to assist you in brewing; automatic variable frequency tiller and mixing improve work efficiency;

4.Adopting advanced world famouse brand components to ensure the smoothly running;

5.Support different heating way, steam, direct fire and electric, depending on site and local utility costs.

6.High-quality stainless steel material 304 or 316 and exquisite appearance.

7.Brewing vessel and fermentation tanks are tested prior to shipment to avoid on-site repairs, guarantee uninterrupted startup and assured vessel performance.

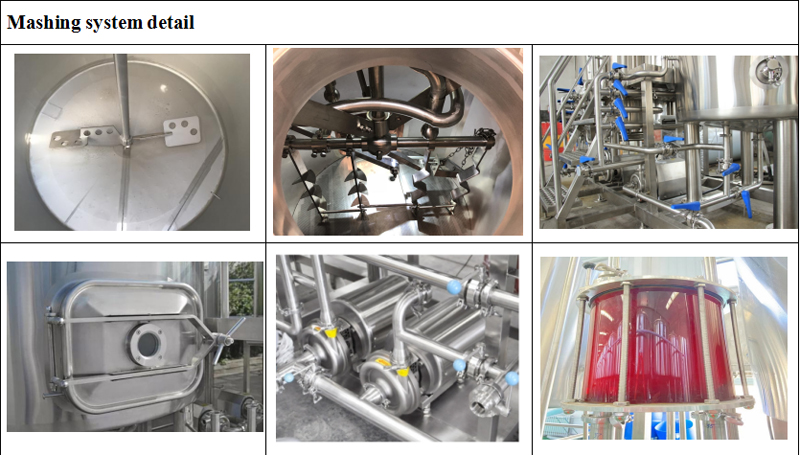

II.Product detail: 2000L beer brewing unit

Specifications

Brewhouse Capacity: 2000Litre/brew with hot water tank

Heating way: steam.

Materials: SUS 304 or 316 Stainless Steel

Interior Finish: Acid washing and passivation or mirror polishing

Polishing Precision: 0.2~0.4μm

Standard Configurations

2.Combined Brewhouse System, 1000L-5000L:

1).Mash tun

Function: Malt mashing

1.Inside surface: packling pasivation or mirror polishing.

2.Manhole, top glass manhole with LED sight.

3.Temperature measurement method: PT100 temperature probe.

4.Heating system: steam heating with jacket, the jacket thickness is 1.5mm.

5.Cleaning method: 360°Fixed rotate cleaning ball.

6.Machinical Agitation: With VFD control, at the top horizontal motor with seal.

7.Steam venting chimney with anti backflow pipe.

8.With level display and necessary valve.

2).Lauter tank

Function: lauter, filter the wort.

1.Inside surface: packling pasivation or mirror polishing.

2. Top sight glass manhole with LED light, size: 450mm.

3. Cleaning: 360°CIP cleaning spay ball on the top.

4. Sparging pipe for grain washing with TC connection.

5.Wort collecting pipe and back washing device to cleaning false bottom.

6. Mechanical Raker: VFD control, stirring motor on the top.

7. Spent grain:Automatic raker device, Grain removing plate with reverse, forward is raker, reverse is grain out.

8. Milled false bottom: 0.7mm distance, diameter designed suitable for the lauter tun, with dense supporting leg, detachable handle.

9.Wort circulation inlet TC on top with elbow and mash inlet upon false bottom on side wall.

10.Side mounted spent grain port .

11.With discharge hole, thermometer PT100 and necessary valves and fittings.

3).Brew kettle

Function: Wort boiling, hopping and whirlpool

1.Inside surface: packling pasivation or mirror polishing.

2. Manhole, top glass manhole with LED sight.

3.Temperature measurement method: PT100 temperature probe.

4.Heating system: steam heating with jacket, the jacket thickness is 1.5mm.

5.Cleaning method: 360°Fixed rotate cleaning ball.

6. Steam venting chimney with anti backflow pipe.

7. With level display and necessary valve.

4).Whirlpool tank

Function: whirlpool

1.Inside surface: packling pasivation or mirror polishing.

2. Manhole, top glass manhole with LED sight.

3.Cleaning method: Double 360°Fixed rotate cleaning ball.

4.Whirlpool tangent pumped at 1/3height of the tank

5. With level display and necessary valve.

5).Hot liquid tank

Function: hot water heating

1.Interior finish: packling pasivition without dead corner.

2.Heating method: steam heating, steam jacket 1.5mm.

3.With Upper manhole 400mm, glass level display with scale, CIP rotary Spray ball.

4. All necessary valves and fittings;

6).Brewhouse pipes

Function: wort transfer from mash tun to lauter, and to kettle and so on.

1.Material: SS304 sanitary pipes.

2.Sanitary stainless steel valve and pipeline, Easy to operate and reasonable in design;

3.Production: Arc welding, polished inside and outside, no welding dead to ensure fluid quality.

7).Plate heating exchanger

Function: wort cooling.

1.Two stage and six flow, hot wort to cold wort, tap water to hot water, glycol water recycle.

2.Design Structure: Suspension type, screw material

is SUS304, nut material is brass, easy disassembled

for cleaning.

3. Stainless steel 304 material

4.Design pressure:1.0 Mpa;

5.Working temperature:170°C.

6.Wort inlet and outlet diameter is φ38

7.Glycol water inlet and outlet diameter is φ38

8.Tap water inlet and outlet diameter is φ38

9.Tri-clamp quick-installed.

8).Work platform

1.Stainless Steel Material, Non slip metal floor

2.Every weld to a smooth sanitary finish;

3.Easy to Cleaning and Protect the Worker, Compact design.

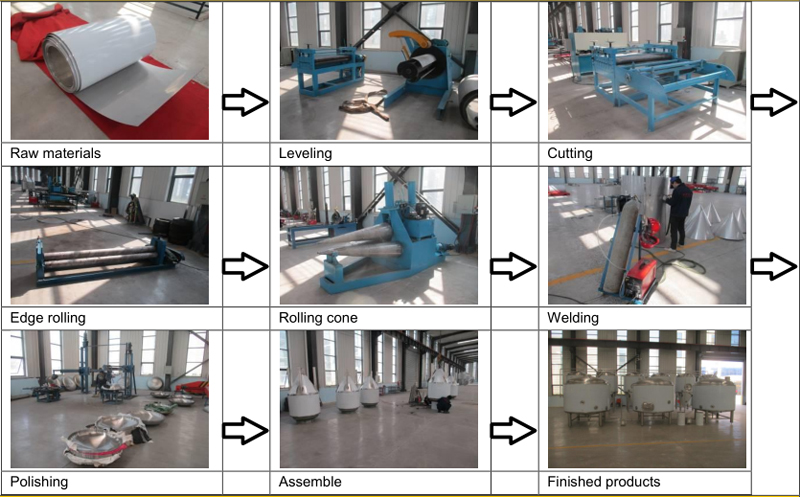

III.Production Process

Jinan Alston Equipment Co.,Ltd.

Jinan Alston Equipment Co.,Ltd.