Energy Efficiency in Breweries Practical Steps

Energy-efficient equipment: Invest in high-efficiency boilers, refrigeration systems, and pumps to reduce energy consumption.

Process optimization: Streamline brewing operations to minimize energy use—for example, using heat exchangers to transfer heat between processes can significantly save energy.

Lighting: Replace traditional lighting with LED fixtures and install timers or motion sensors to turn off lights when not in use.

Insulation: Properly insulate tanks, pipes, and buildings to retain heat in winter and keep interiors cool in summer, lowering energy costs.

Water conservation: Breweries consume large volumes of water, so installing low-flow toilets, faucets, and showerheads can conserve water and reduce energy costs associated with heating water.

Waste reduction: Implement a waste management program to minimize energy required for waste disposal.

Renewable energy: Consider integrating solar panels, wind turbines, or other renewable energy sources to cut energy costs and reduce environmental impact.

By adopting these measures, breweries can save energy, lower operating costs, and minimize their environmental footprint.

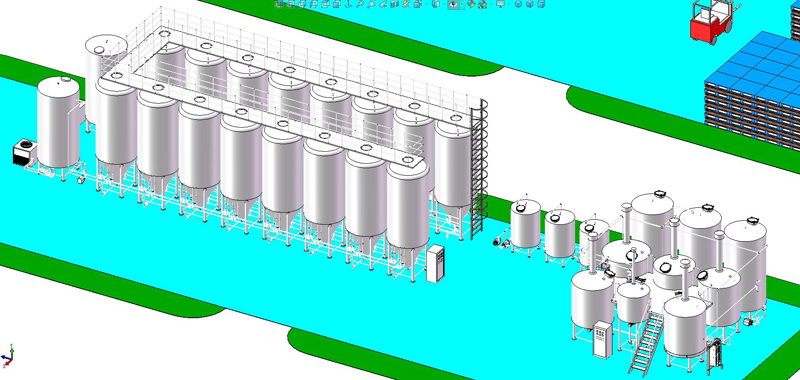

Alston beer brewing equipment Company not only manufactures top-quality brewery equipment for flavor-rich beers but also helps breweries optimize equipment configurations, maximize process uptime, and reduce beer loss during production.

Jinan Alston Equipment Co.,Ltd.

Jinan Alston Equipment Co.,Ltd.