With the beer market being oversaturated, investing in kombucha brewing equipment is a smart move. More and more people are embracing kombucha for its health benefits and unique flavor, and having your own kombucha brewing setup allows you to take advantage of this trend. Quality equipment ensures consistent, delicious batches, which helps me build customer loyalty. It allows for precise control over the brewing process, from fermentation to bottling. Durable, easy-to-use equipment also reduces maintenance issues and production time, making it a convenient and cost-effective investment for the future.

Alston kombucha brewing equipment includes the kombucha brewing skid, kombucha fermentation tank, sugar mixing tank, filter and bottle filler.

1.The core brewing process as below:

The main kombucha making process includes tea boiling, fermenting, carbonation, filtering and filling. Kombucha kettle can use electric heating or steam heating depends on the kettle size from 100L to 5000L.

The tea kettle/sugar mixing tank firstly boil the tea and mix the sugar before transfering to the fermentation tank

A hot water tank can be considered if you want to do continious brewing

Use plate heat exchanger after boiling for quickly cooling the hot tea

Use bag filters to filter the tea before going into fermentation tank

Transfer the tea liquid to the fermenter for 15days fermentation

Carbonation is required if you want your kombucha contain Co2

Filtering the fermented kombucha before bottling it

Filling into bottles or other models for selling in the market

2. Kombucha Equipment Components

-Kombucha brewhouse:

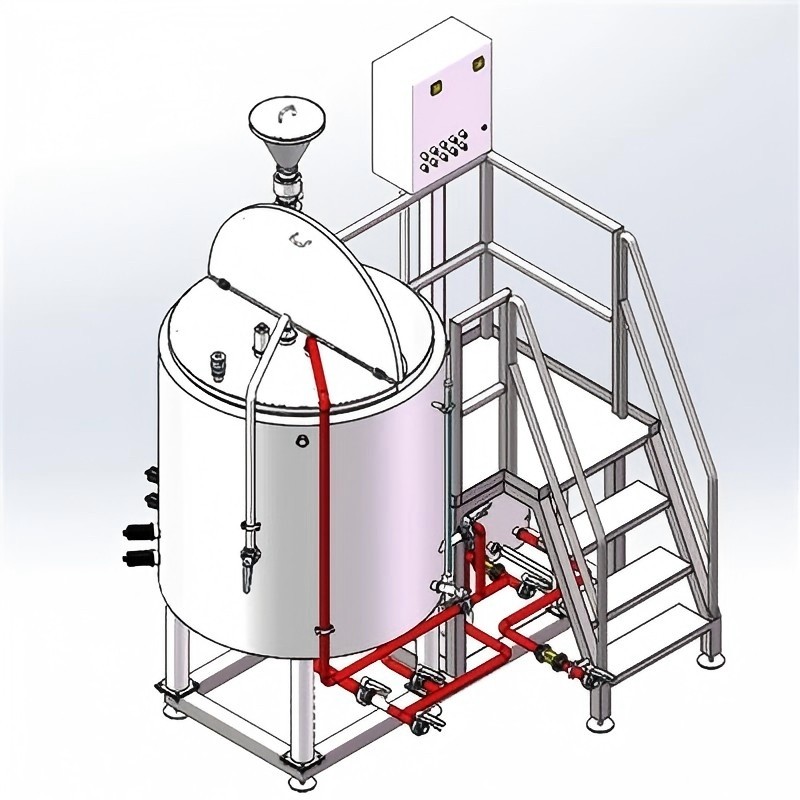

It includes mash tun, boil kettle, hot liquor tank, etc. It is for water boiling, add sugar and tea steeping, mix by agitator. It can be heated by steam boiler/direct fire burner/electric tube.

-First stage open top kombucha fermentation tank:

Aerobic open top fermentation tank, also work as SCOBY storage tank, ferment in room temperature.

The function is store SCOBY and produce ‘starter liquid’ at room temperature.

-Second stage pressure fermentation tank:

For kombucha fermentation and flavouring.

-Storage tank/Brite tank:

Filtered Kombucha storage and carbonate/fizzy the Kombucha for package.

-Filter Kombucha by DE filter and Membrane filter:

DE filer is coarse filter, it can make Kombucha clear. Membrane filter is fine filter, it can filter bacteria.

-Glycol cooling system:

It includes Glycol Water Tank, Glycol Water Chiller, Glycol Water Pump and Pipeline.

-Control cabinet:

It is for temperature control, pump control, motor control.

-CIP cart:

It is for all tanks cleaning.

Kombucha is a popular fermented tea drink that has gained a lot of popularity in recent years. If you are interested in starting a kombucha business and look for kombucha brewing equipment, Alston company supply complete kombucha production line.

Jinan Alston Equipment Co.,Ltd.

Jinan Alston Equipment Co.,Ltd.