Full Automatic Keg Filling Line

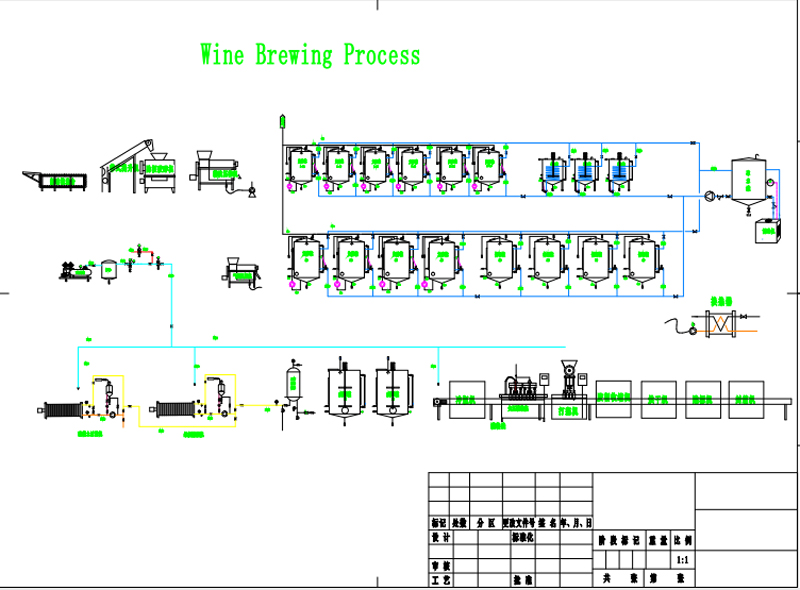

1.Keg filling line solution and capability design

A full set of equipment is a cleaning and filling line host of 1 connected structure, a set of 10000L/H instantaneous sterilization machine,

a set of 10000L buffer tanks (with a CIP pump), a set of automatic weighing and launching devices;

A set of chain transport system for automatic transportation of beer buckets, and related supporting steam decompression, filter composition.

The equipment is designed according to the customer's needs based on the standard stainless steel insulation barrel of 50L stainless steel,

and the ability to design 120 barrels/h for other configurations of the cleaning and filling line is designed.

2.Equipment basic structure and workflow:

1).Equipment Structure:

The cleaning and filling line system uses a U -shaped placement structure, and the direction of the barrel and the barrel is kept parallel.

The side of the barrel contains a set of pre -washing machines, a set of barrels external cleaning (cleaning method: barrel rotation hair brushing brushing), inner wall cleaning and filling machine, a set of automatic weighing systems and unqualified launch devices, a set of conjoined CIP system for washing the inner wall of the barrel.

The device is generally placed in a U -shaped, the barrel and the cleaning line and the outlet chain are parallel to the barrel, which is located in the keg in and out of filling line.

The CIP system for washing the inner wall of the barrel is located on one side of the irrigation line structure to save space. Cleaning and filling lines are connected to pipelines such as the CIP system and external compressed air, CO2, steam, and liquid in the inner wall of the barrel with the inner wall of the barrel.

2).Working process:

The unwashed beer barrel is placed on the transport chain of the inlet barrel by manual way (the wine spear is down), and the beer barrel will be transported to entrance position of the cleaning and filling line by the conveying chain;

Under the control of the program, the cleaning and filling line moves the barrel to the position of station 1 through the barrle feeding and shifting device to start washing;

After the cleaning process of station 1 is completed, the barrel shifting device starts to work, and the barrel is moved from station 1 to station 2 to start the cleaning process in station

At the same time, the barrel shifting device moves the next barrel to station 1 for the cleaning process in station 1.

Through each bucket movement, make each bucket according to the flow in station 1 - station 2------ station 6 to complete the cleaning, sterilization, filling process.

The finished product after filling is pushed to the barrel conveyor chain through the barrel shifting device of each line, and then transported to the weighing device for weighing through the conveyor chain;

Qualified weight products are transported through the conveyor chain to the finished product area, and unqualified weight products are pushed to the unqualified weight area when passing through the weighing push-out device.

Full Automatic Keg Filling Line

- Product Detail

Jinan Alston Equipment Co.,Ltd.

Jinan Alston Equipment Co.,Ltd.